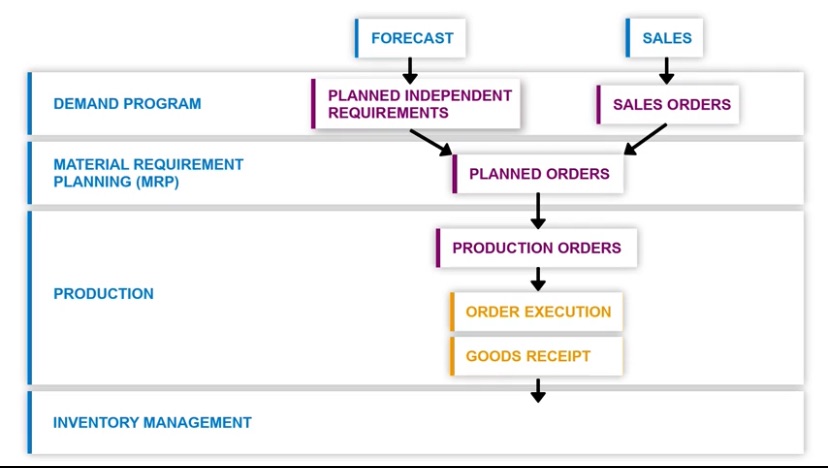

Supply Chain Planning is essential to ensuring that products are available when needed, with minimal cost and waste. It can be broken down into three major steps:

Forecasting:

- Definition: The process of estimating future product demand based on historical sales data, market analysis, and seasonal trends.

- Example: A retail company analyzes the past three years of sales data to predict how much inventory they’ll need for the upcoming holiday season.

Demand Management:

- Definition: The process of balancing customer demand with the company’s supply capabilities, ensuring that products are available without overproducing or underproducing.

- The following main methods are available for including customer requirements into planning:

Make-to-Order Production: Each sales order item is planned separately.

Make-to-Stock Production: Production can be triggered without specific sales demand. - Example: A food manufacturer adjusts their production levels of a popular snack based on promotions and consumer buying patterns during the summer.

Material Requirements Planning (MRP):

- Definition: A system that calculates the materials and components needed for production and schedules their procurement based on production timelines.

- Example: An automotive manufacturer uses MRP to ensure that all parts needed for assembling cars are available on time to meet the projected demand for the next month.

In SAP S/4HANA Manufacturing, there are four primary production types:

- Discrete Manufacturing: Produces distinct items based on individual production orders, suited for industries like automotive and machinery.

- Process Manufacturing: Used for batch-oriented production, ideal for industries like chemicals and pharmaceuticals.

- Repetitive Manufacturing: Focuses on continuous, high-volume production, often without production orders.

- Kanban: A lean manufacturing method that supports just-in-time production by using a demand-driven, pull-based system.

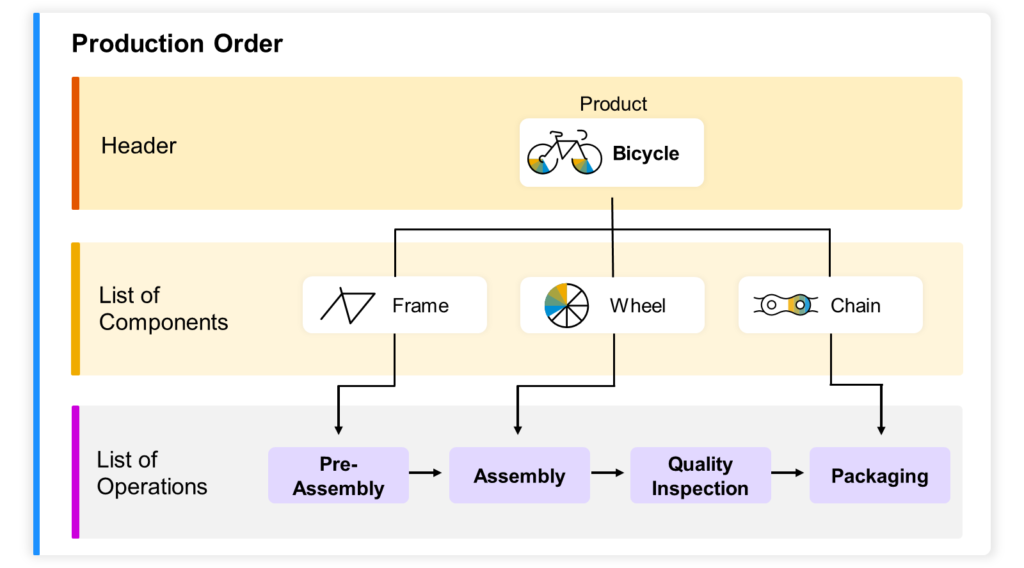

Production orders in SAP S/4HANA include several key details for managing the production process:

- Product Details: Specifies the type of product, such as mountain or children’s bikes, to be produced.

- Quantity: Defines how many units of each product type are required.

- Timing: Establishes the production timeline, indicating when each unit should be produced.

- Material Components: Lists the raw materials needed for production.

- Operations and Work Centers: Specifies the steps required and the work centers where these operations will occur.

Structure of a Production Order